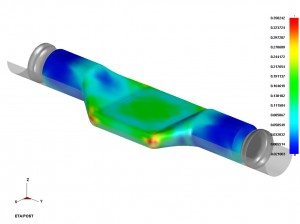

The Finite Element Analysis or FEA is a computer based simulation model that utilizes numerical techniques to analyze the effects of various material reactions to specific conditions. By simulating factors such as stress intensity, fluid flow, and heat transfer, engineers are able to determine part feasibility as well as make design suggestions. At American Hydroformers, we use FEA simulations to analyze the effects of the forming parameters during the tube hydroforming process. This tool allows our engineering department to determine if your part has the potential to be manufactured by hydroforming. By using FEA simulations we can identify design flaws while calculating component displacements, strains, and stresses under multiple conditions. This helps to replace experimental testing and the expense of trial tooling. The objective of our hydroforming FEA simulations is to help identify the optimal internal pressure for a hydroformed tube. This allows us to produce part with greater structural stiffness, maximum strength, uniformity of tube wall thickness, and better overall part integrity.

- Greater Structural Stiffness

- Minimize Severe Thinning

- Optimal Pressure Path

- Maximum Strength

- Uniformity of Tube Wall Thickness

Autoform Hydro Simulation

At American Hydroformers, our in-house capabilities include the utilization of AutoForm Hydro simulation software. Our team of engineers are trained and regularly updated on this software which provides a comprehensive understanding and analysis of the entire hydroforming process. By employing this software in-house, we supply our customers with rapid verification, shorter development time, and improved process reliability.

- Easily Identify Forming Issues

- Rapid Tool Design

- Accurate Springback Simulation

- Quality & Cost Improvements

- Reduced Development Time

- Improved Reliability

- Lower Material & Production Costs