Finite Element Analysis: One Concept Fledgling Firms Shouldn’t Overlook

If you are relatively new to the manufacturing or construction field, the term finite element analysis may seem both unfamiliar and intimidating. However, we assure you that it’s one concept well wort …

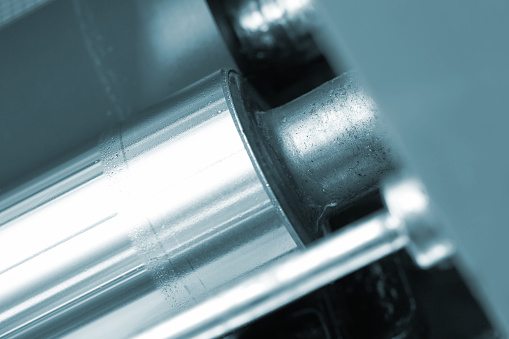

What is Tube Hydroforming?

Tube Hydroforming is a type of die forming that is used to shape certain metals, including aluminum and stainless steel, into strong but lightweight pieces. This method is often used in the automotive …

Finite Element Analysis strengthens hydroformed parts and customer relationships

When your product represents a structural component of your customer’s purchase it sure better be structurally sound. Who can afford a costly recall or, even worse, be responsible for a personal accid …

The Power of Hydroformed Components

More and more companies are becoming aware and taking advantage of wind energy and its environment friendly benefits. This refreshing pursuit of clean alternative energy has led to a global increase i …

Metal Stamping and Hydroforming: High-Quality Work at a Low Cost

When you are working with metal, you will find that there are a variety of options and tools available for you to use. Although there are so many options for you to choose from, many companies decide …