American Hydroformers: The advantages of deep draw hydroforming

If you need a lightweight metal part with a depth larger than the radius, deep draw hydroforming is the way to go. This versatile process makes lightweight, durable parts that are deeper and more accu …

Deep Draw Hydroforming Aids in Medical Device Manufacturing

It has long been established that deep draw hydroforming is a technology that has staying power. The process in which deep draw hydorforming follows makes it a powerful solution for a variet ...

Deep Draw Hydroforming Innovations

September brought glad tidings in the world of deep draw hydroforming. Not only have power player Beckwood Press Company announced improvements in the area of low-volume, high-mix production, but it w ...

Deep Draw Hydroforming Process

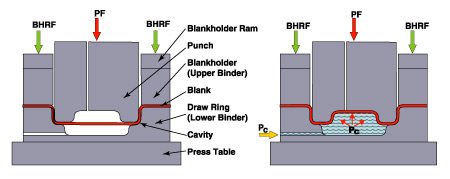

What is Sheet Metal Hydroforming? Sheet metal hydroforming is a metal forming process that is achieved by applying force to sheet metal to alter its overall geometric shape as opposed to added or sub ...

Deep Draw Hydroforming Explained

In the metal forming industry 'hydroforming' has become somewhat of a buzzword and general term for metal shaping. But there are many ways of shaping metal in this industry, all with their own unique ...

The Deep Draw Hydroforming Process & Advantages

In the 1940s, deep draw hydroforming became the forefront method for developing and manufacturing irregular shaped metal parts. Die style stamping became archaic, as it became inefficient in compariso ...