7 Benefits of Hydroforming

A cost-effective way of forming certain metals into strong lightweight structures is by hydroforming. This can be done with aluminum, brass, low alloy steels and stainless steel. Starting with a blan ...

What is Tube Hydroforming?

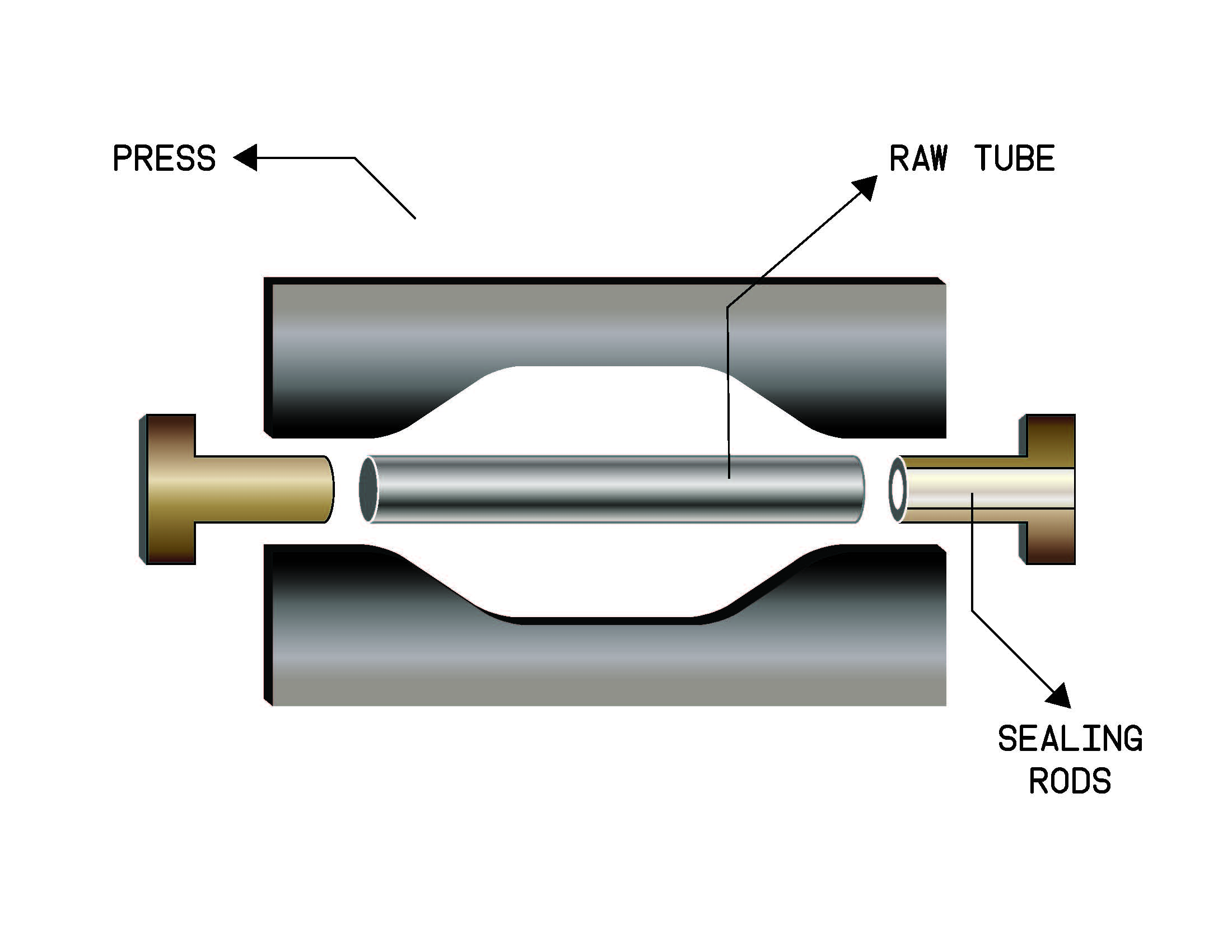

Often, when it comes to discussing what we do, the very first question asked is: What is tube hydroforming? The simplest answer is that hydroforming is a way to shape metal. This cost-effective proces ...

Innovative Uses of Sheet Hydroforming

Most consumers are already fairly well aware that one of the most common applications of sheet hydroforming is found in the automotive sector. For years, auto makers have taken advantage of hydroformi ...

The History of Hydroforming in the U.S.

Hydroforming is defined as the process in which metal is shaped using fluid dynamics. The result is lightweight, structurally strong, stiff pieces of the original metal. Metals that can be hydroformed ...

Hydroforming Makes Offshore Wells Safer?

From durable auto bodies to high-tech bicycle components, the hydroforming process is well-known for breaking technological barriers on land. Now, engineers in the offshore oil and gas industry are l ...