Two Musical Instruments with Hydroformed Components

While most of us tend to associate hydroforming with the automotive and cycling worlds, other industries make good use of hydroformed components as well. The music industry is one of them. Apart from …

Hydroformed Components Keeping American Commutes Healthy and Affordable

Hydroformed Components Keeping American Commutes Healthy and Affordable. Recently there has been a sudden uptick in the number of people who bike to work instead of driving cars or taking public trans …

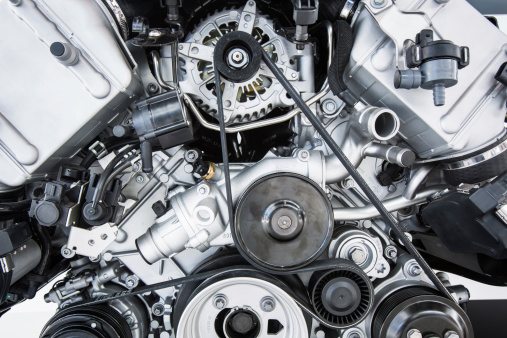

Advantages of Hydroforming in the Mid-West

The advantages of hydroforming are many. Mostly, they revolve around material efficiency, speed and cost savings. Traditional deep drawing methods suffer from the effects of drawing stress (on the mat ...

American Hydroformers Can Take You from Prototype through Production

Whether you’re looking to build a prototype fresh from the drawing board or to manufacture your already proven components on a small or large-scale, American Hydroformers can handle your fabricating n …

Tube Hydroforming Updates: News Snippets from Around the Web

Beginning in the 1970’s, the process of tube hydroforming has met the increasing demand for the manufacture of simple, lightweight components. Over the next few decades, this process has developed to …

Finite Element Analysis strengthens hydroformed parts and customer relationships

When your product represents a structural component of your customer’s purchase it sure better be structurally sound. Who can afford a costly recall or, even worse, be responsible for a personal accid …

The Power of Hydroformed Components

More and more companies are becoming aware and taking advantage of wind energy and its environment friendly benefits. This refreshing pursuit of clean alternative energy has led to a global increase i …

Metal Stamping and Hydroforming: High-Quality Work at a Low Cost

When you are working with metal, you will find that there are a variety of options and tools available for you to use. Although there are so many options for you to choose from, many companies decide …

Friction Stir Welding Brings Alloys Together

The process of friction stir welding is a relatively new way to join metal components together. It is a metal joining method that has applications in industrial fabrications and manufacturing such as …

Deep Draw Hydroforming Benefits Your Daily Life

As deep draw hydroforming continues to become a reliable and viable source of production, people who rely on hydroformed parts can only benefit from its persistent innovation.

Information about new a …