Friction Stir Welding meets the Auto Industry’s High-Volume Standard

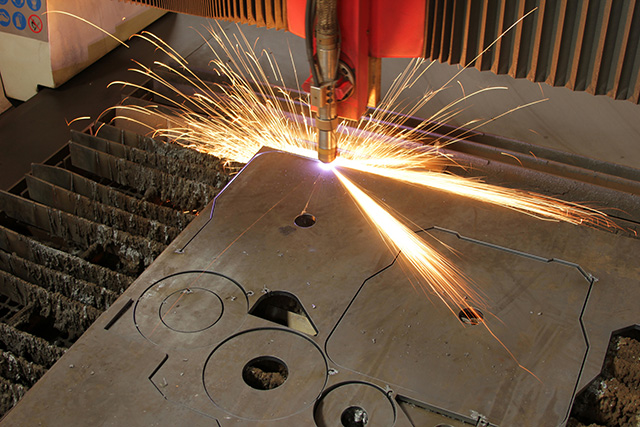

It’s one thing to join pieces of metal together; it’s another to do so without changing their microstructure. The solid state joining process that uses frictional heat generated by a rotating tool has been used for a variety of applications across such industries as aerospace, automotive, shipbuilding and rail. Today, FSW meets the auto industry’s high volume standard and does so in five ways.

Friction Stir Welding meets the Auto Industry’s High-Volume Standard

Friction stir welding for the automotive industry “[has] the ability to create highly durable customized components for everything from commercial to personal use vehicles…” Here is how essential it is to the automotive industry.

AUTOMATED FOR HIGH VOLUME PRODUCTION

Friction stir welding allows for high-volume production. Parts created are more efficient. Low force friction welding generates faster cycle time from traditional friction welding. If it’s steering components, u-joints, or camshafts, friction welding gets it done when needed. Also, automated machines reduce the overall cycle of time to produce the part.

CONSISTENCY

The need to produce a product the same each time is key for the auto industry. The friction welding creates parts that are always the same and of top quality. This makes FSW technology more advanced than conventional welding technology. And such consistencies dissolve any worries from suppliers because there’s no down-time. There’s also friction welding machines to make it easier for operators since it produces defect-free parts.

ABILITY TO JOIN DISSIMILAR METALS

The ability to forge different metals together, such as joining aluminum and copper, has become a critical aspect to the automotive industry. Friction stir welding allows the joining of different metals, and this gives a stronger and lighter weight that is always consistent.

PROVEN-EFFECTIVE MANUFACTURING FOR THE INDUSTRY

When friction welding keeps producing certain types of parts for decades and proves effective, that’s key for the automotive industry. These parts include the monosteel piston, brake calipers, transmission input shafts, and transmission gears. As more applications see benefits, more of a part range will exist.

FRICTION STIR WELDING RELIABLE PROCESS

When there’s a demand for parts, the automotive industry produces, not before. This means the automotive industry runs on Just-in-Time Inventory. To operate this way, the parts produced have to be reliable. FSW technology is reliable, with no machine downtime.

There’s a YouTube demonstration of an F 1300 FSW machine to see how metals join. For additional information, contact us.

Leave a Reply