What is Hydroforming?

What is hydroforming? Hydroforming is an innovative method of pressing metal into the desired shape. It produces results similar to cold forming, but instead of simply pressing the metal with a mold ...

Tube Hydroforming Process Leads to Amazing Bicycles

Though tube hydroforming has humble roots, it has taken those roots and firmly planted them in industry, design, and innovation. For instance, take a look at how much innovation has gone into bikin ...

Tubular Hydroforming And Other Innovative Techniques

Whenever you are working on a project, no matter how big or how small, you should always look for the best possible way to make the project successful. When you want the project done correctly, it doe ...

Hydroforming Aluminum Vs Stamped Steel

The rise of hydroforming as a viable manufacturing process which reduces the weight of resulting items is driving two distinct transitions in the industry. One of these is the switching from stamping ...

2016 CAFE Standards: What the Near Future Holds

Beginning in 2011, automobile makers had to meet a set of government regulations that had sat in limbo for many years. For many, this was the biggest change in fuel-economy standards since the 1970s C ...

American Hydroformers, Inc. to be Featured on the Science Channel/Discovery Channel’s “How It’s Made” Television Program.

SUMMARY: American Hydroformers is proud to announce that the company will be featured on a segment of the Science Channel/Discovery Channel’s popular “How It’s Made” television program. This detailed ...

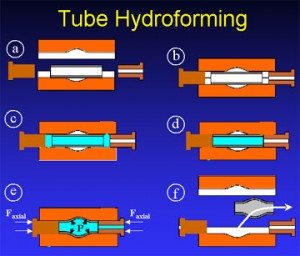

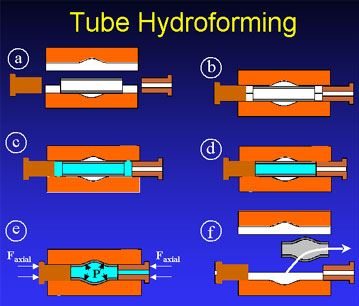

What is tubular hydroforming?

What is tubular hydroforming? Tubular Hydroforming is a cost effective way of shaping pliable metals such as aluminum, brass, and low alloy stainless steel. The process has been used since the 1950's. ...

What is tube hydroforming and how is it used?

One of the questions we get asked a lot about our business is: what is tube hydroforming and how is it used? In order to understand tube hydroforming, perhaps one should first understand hydroforming ...

What is tube hydroforming?

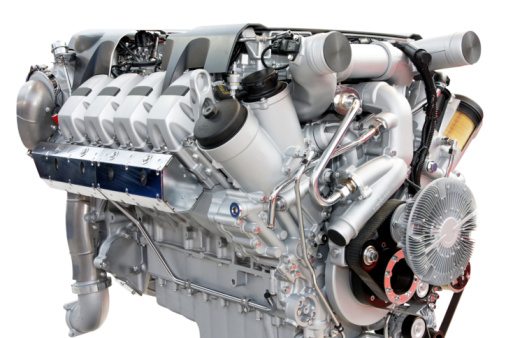

Hydroforming is the process of using high pressured water to create custom metal structures to fit the needs of our clients. Centered in the Midwest since 2003, we have catered to a number of clients' ...

The art and the ingenuity of hydroforming

Hydroforming is not only a cost effective metal fabrication and forming process when compared to traditional stamped and welded parts, but it can also be a bit of art and ingenuity. Virtually all meta ...