What is Hydroforming and Why Use It?

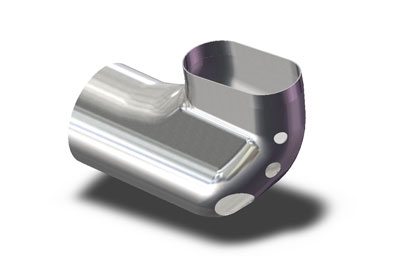

When many think about the manufacture of metal parts for cars, bicycles, and such, they often think of such processes as solid die stamping, However, in the late 1940’s and 50’s a new process calle ...

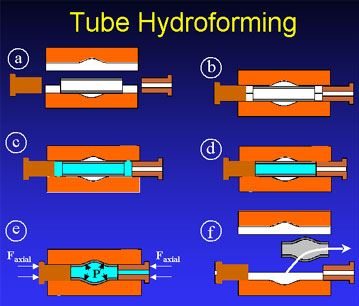

What Is Tube Hydroforming? All you need to know.

Whether you are well-informed or brand-new to the subject, here is a primer on the basics of tube hydroforming. Read on to discover more about the process, the materials, the products, and the benefit ...