Tube Hydroforming: An Effective Solution

There is a good chance that the majority of the things you use on a regular basis were created using a hydroforming process. The vehicle you drive every day and the bicycle your children ride every day after school were built using a hydroforming process. Hydroforming is an effective and efficient process that is used to form metals. The hydroforming process holds a variety of features that make it an increasingly popular choice in a variety of industries, including the automotive industry.

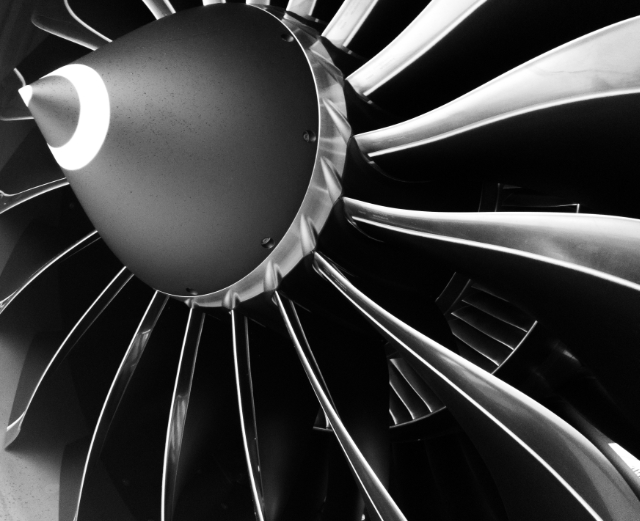

Tube hydroforming is a method used to create bellows that are commonly used in the automotive and aerospace industries, among others. The bellow tubes that are created are flexible tubes that can easily transport liquids or gases. The thickness of the bellow wall will depend on a variety of things, including how the bellow wall will be used. Some products will need bellows that fit in small or tight corners; the hydroforming process ensures that you will be able to create the bellow wall that you need based on the characteristics.

Tube Hydroforming and Metal Forming

Hydroforming presents an affordable and suitable solution because it will offer an incredible amount of benefits. One of the key benefits that tube hydroforming can offer is that the method will make it possible for you to create the tubes that you need based on the specific requirements. When you use the tube hydroforming process along with bellows, the bellows will have the ability to occupy some of the shakes and other pressures that could have an impact on other parts.

The tube hydroforming process can also reduce the weight of cars, trucks, and other automobiles. The weight of these products can be reduced because the tube hydroforming process can be used to combine parts and customize the thickness of the walls. If you are interested in learning more about tube hydroforming and how it can be used to create the effective and efficient parts you need during your next production, please do not hesitate to reach out to us today.

Leave a Reply