Unlocking the Power of Hydroforming: A Comprehensive Guide

Welcome to American Hydroformers’ blog! Today, we’re diving deep into the fascinating world of hydroforming, exploring its intricacies, applications, and the innovative solutions it offers across indu …

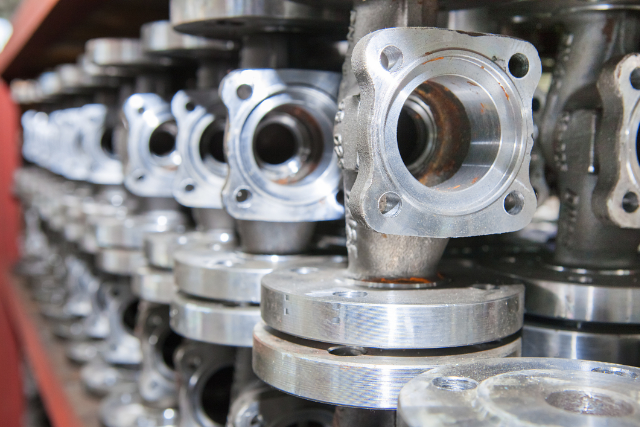

American Hydroformers Can Fulfill Your Needs For Metal Stamping

American Hydroformers and metal stamping. The metal stamping process consists of the transformation of sheet metal into parts and components that can be used in various industries. Just as with differ …

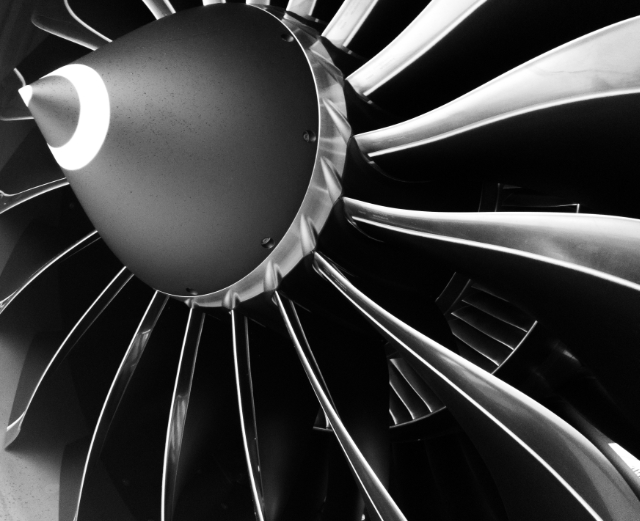

Create The Strong Products You Need With Hydroforming

Hydroforming has been widely used in the United States for decades. Hydroforming has been used to produce a long list of parts and components in the automotive industry, along with other industries. T …

Get the Facts About Tube Hydroforming

Get the Facts About Tube Hydroforming

There are two common types of hydroforming, tube hydroforming, and sheet hydroforming. But first, what is ‘hydroforming?’ It’s the process by which metals like …

Will COVID-19 Affect the Friction Stir Welding Market?

Will COVID-19 Affect the Friction Stir Welding Market? If you were to run an internet search on “long-term effects of COVID-19,” the results would include headlines of every variety, from long-term he …

3 Benefits of Metal Stamping: American Hydroformers

Many people may not realize this, but metal stamping is an essential piece to the manufacturing process that provides many benefits to companies of all sizes. In order to gain a better understanding o …

Creating Bellows With Tube Hydroforming

Creating bellows with tube hydroforming. At American Hydroformers, we are excited to have tube hydroforming as one of our popular services. If you are not sure what tube hydroforming is, we are glad y …

What Makes The Deep Draw Hydroforming Process Work?

One of the most important processes in manufacturing is metal forming. The metal forming process is available for the effective production of a variety of products and components. One of the methodolo …

CAFE Standard: Superheroes Aren’t the Only Beneficiaries

CAFE Standard: Superheroes Aren’t the Only Beneficiaries. From time to time, news stories will flood the channels of humans performing remarkable feats of strength. These amazing displays generally ta …

Tube Hydroforming: An Effective Solution

There is a good chance that the majority of the things you use on

a regular basis were created using a hydroforming process. The vehicle you

drive every day and the bicycle your children ride every da …