Automated Hydroforming Process using Robotics

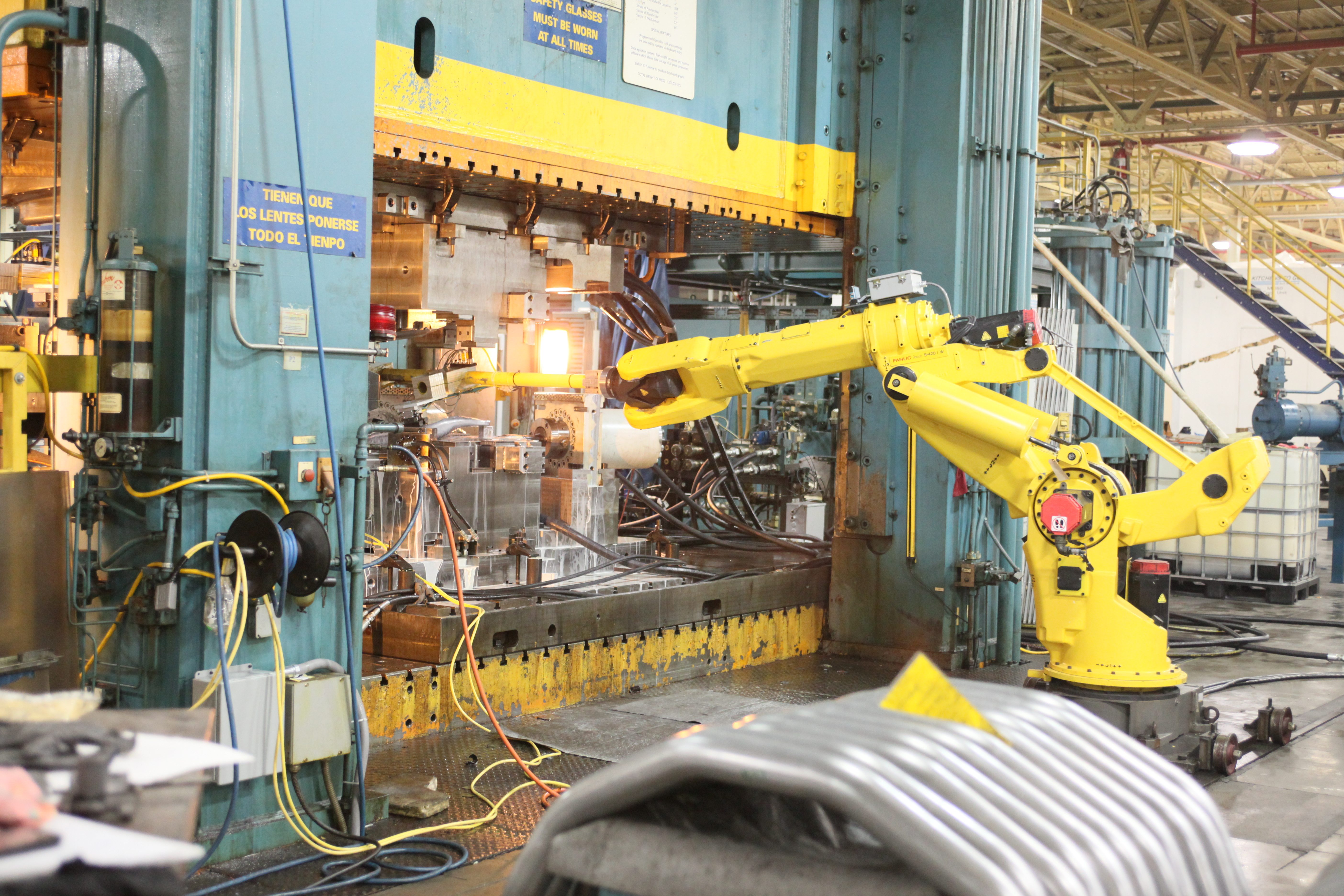

American Hydroformers announces the addition of a new automated hydroforming cell to augment current capabilities and production capacity.

Fort Wayne, IN–In an effort to continuously improve the efficiency, speed, capacity, and accuracy of their hydroforming process, American Hydroformers has implemented a new automated hydroforming cell. With the addition of multiple robotically automated stations, American Hydroformers has not only increased production capabilities but also improved overall part precision. Click here to watch the video of the 3 robots working in the cell.

The automated hydroforming cell employed by American Hydroformers provides a more efficient production process. By producing hydroformed parts and components faster and more cost effectively, overall part prices and turnaround times are reduced. Additionally, by utilizing a completely automated system, American Hydroformers can also better control material costs by reducing waste and scrap.

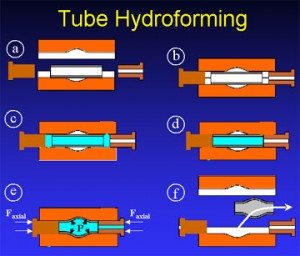

Unlike other metal forming techniques, hydroforming allows for more complex shapes, increased part strength, lower part weight, and greater design flexibility, while also improving overall part quality. Additionally, hydroforming offers tighter part tolerances with a reduction in the overall manufacturing steps required.

Founded in 2003, American Hydroformers specializes in the tube hydroforming manufacturing process. Our capabilities include numerous metal forming techniques such as hydroforming, hydraulic press work, metal stamping, and tube forming. In addition to hydroformed components, American Hydroformers offers complete assembly level fabrication of automotive structures, robotic welding, and both industrial laser and plasma cutting.

To learn more about American Hydroformers, visit our website at https://americanhydroformers.com/

If you need a hydroforming provider or wish to learn more about our business, contact us today for more details.

Error: Contact form not found.

Leave a Reply