Hydroformed Components

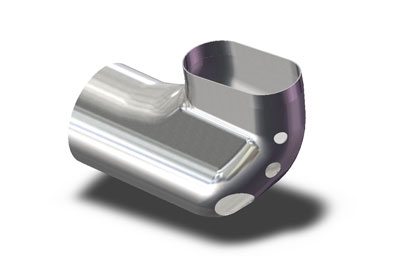

What do a satellite antenna, an aluminum frame bicycle and the engine cradle of your neighbor's motorcycle have in common? Chances are they were all made with hydroformed components. From the medical ...

Tube Hydroforming vs. Metal Stamping

Today, nearly all businesses that desire to form parts have concerns regarding the strength, weight, and cost of a component. Metal stamping has been a traditional metal forming procedure. It does not ...

Tubular Hydroforming

Most of us have never considered the world of hydroforming or tubular hydroforming. The components made from these methods have permeated a great many areas of our lives from the vehicles we drive to ...

Accuracy in tube hydroforming

As the demands for lightweight construction and precision grow, tube hydroforming is becoming increasingly popular. Hydroforming is used in a wide variety of applications from industry parts to bikes ...

Hydroformed Bicycle Frames

You may think that if you've seen one bike, you've seen them all. Yes, they come in different colors and wheel sizes with different kinds of brakes; but they're basically all the same. After all, they ...

Advantages of Tubular Hydroforming

Any item that is built with a metal tube can be made more efficiently and cost-effectively with tubular hydroforming. The process was first developed and used in the 1950s. The disadvantages of pressi ...

Improving the World with Hydroforming

Hydroforming is a cost-effective way of shaping ductile metals into stiff, strong and lightweight pieces. Practically all metals that can be cold formed are suitable for hydroforming, and without bei ...

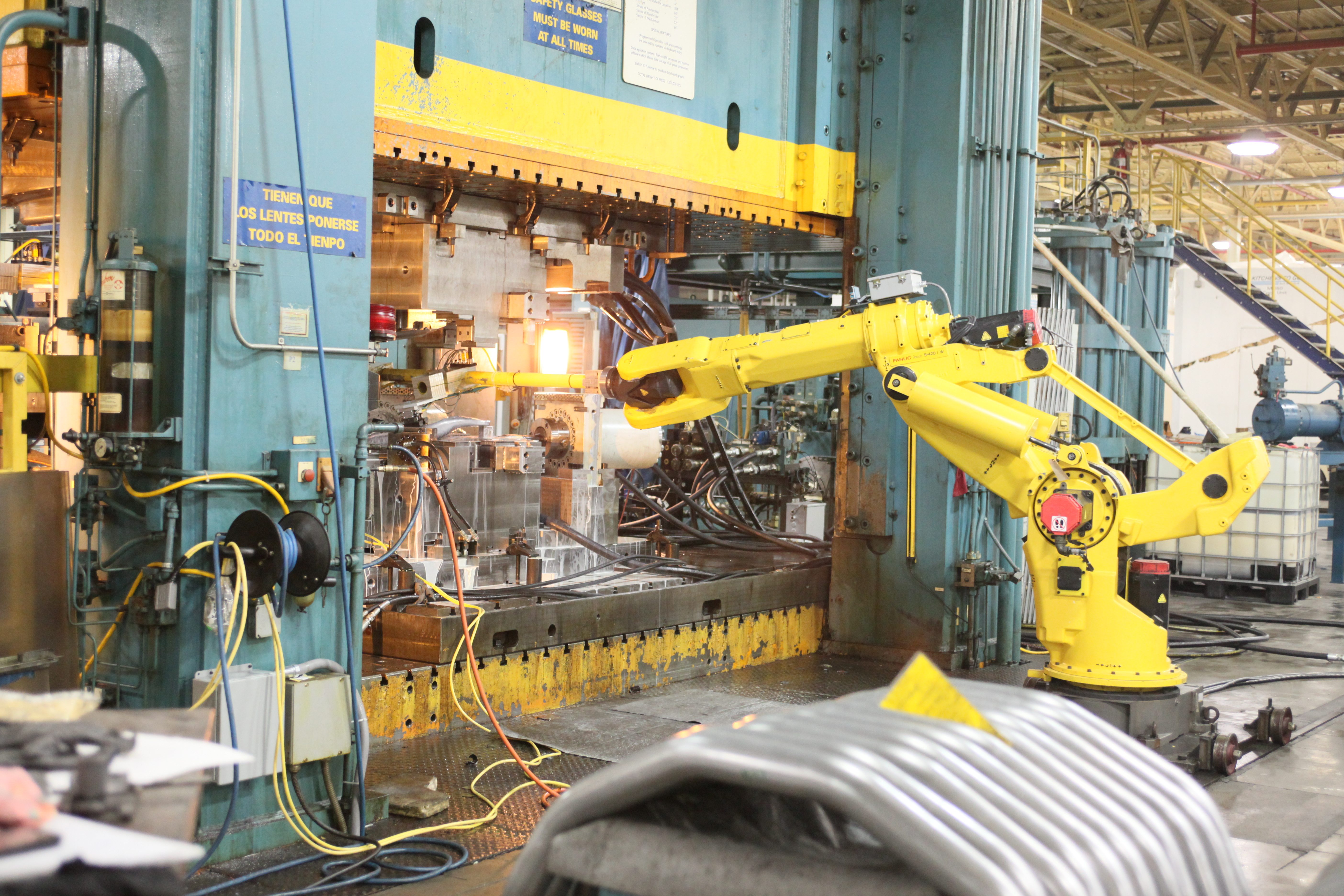

Automated Hydroforming Process using Robotics

American Hydroformers announces the addition of a new automated hydroforming cell to augment current capabilities and production capacity. Fort Wayne, IN–In an effort to continuously improve the effi ...

What is Hydroforming and Why Use It?

When many think about the manufacture of metal parts for cars, bicycles, and such, they often think of such processes as solid die stamping, However, in the late 1940’s and 50’s a new process calle ...

Hydroforming for Performance in the Automotive Industry

Automakers face a number of challenges in providing consumers with vehicles that are safe, fuel efficient and reliable. One way they are achieving these goals is with the use of hydroformed automotive ...