American Hydroformers Can Fulfill Your Needs For Metal Stamping

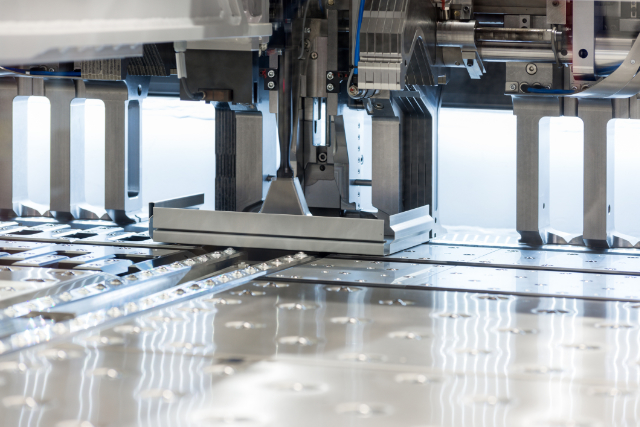

American Hydroformers and metal stamping. The metal stamping process consists of the transformation of sheet metal into parts and components that can be used in various industries. Just as with differ …

What Can Metal Stamping Do For You?

Many people may not realize this, but metal stamping has always been a key part of the manufacturing process in many industries. In order for people to have a better understanding of metal stamping, i …

3 Benefits of Metal Stamping: American Hydroformers

Many people may not realize this, but metal stamping is an essential piece to the manufacturing process that provides many benefits to companies of all sizes. In order to gain a better understanding o …

Why Is the Metal Stamping Market Growing?

Why is the metal stamping market growing? It is no secret that the 2020 global Coronavirus pandemic has had a negative effect overall on the global economy.

While no two countries have faced identi …

COVID-19 and the Metal Stamping Market Outlook

There’s never been another year like 2020. It’s unrivaled in recent history for its global disruption. Here in North America, the ongoing coronavirus pandemic, coupled with political turmoil and socia …

American Hydroformers: Metal Stamping and Hydroforming

The majority of manufacturers will consider metal stamping, hydroforming, and other methods to be processes that are specialized and closely-focused. However, hydroforming and other metal-forming meth …

Debunking 3 Metal Stamping Myths

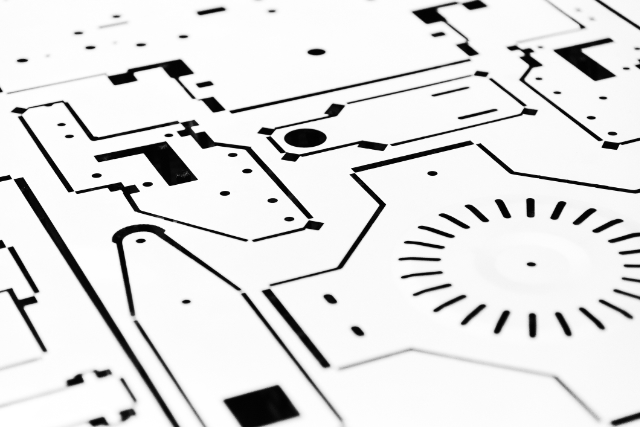

In the manufacturing industry, there are multiple processes that

can compete with one another and still create the same products or products that

are similar. The metal stamping process is one of the …

Metal Stamping Can Be Used To Improve The Production Process

Over the past few years, metal stamping has experienced a significant amount of growth in a variety of industries. One of the contributing factors to the financial growth of the process is the growth …

The Metal Stamping Process

When it comes to metal stamping, the process is not a new process. It’s history can be dated all the way back to the 1800s, and this was during the type when bicycle parts were being mass-produced. Ho …

Metal Stamping: A Versatile Method for Modern Manufacturing

Many business owners associate metal stamping with automotive manufacturing but this method is becoming a popular choice in other industries. Metal stamping, which uses dies and punches to form and cu …