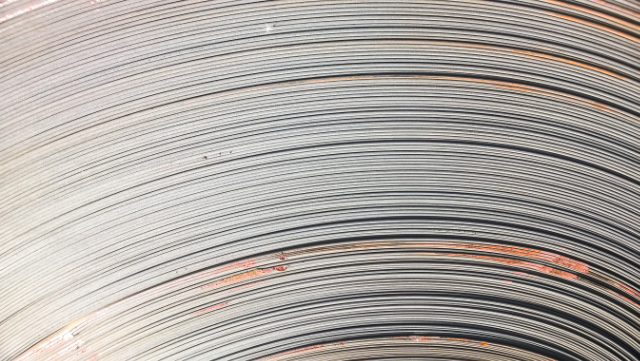

The Metal Stamping Process

When it comes to metal stamping, the process is not a new process. It’s history can be dated all the way back to the 1800s, and this was during the type when bicycle parts were being mass-produced. However, the metal stamping systems and other resources that were being used were not as advanced as they are today. The metal stamping systems during that time were still able to produce a variety of effective and efficient parts and components.

Unfortunately, there have been many misconceptions and myths about the stamping process that have caused a great amount of confusion about the process. The metal stamping process can be a very effective process, and it is one that is also affordable and efficient. The metal stamping process can be used to produce a variety of parts in multiple industries.

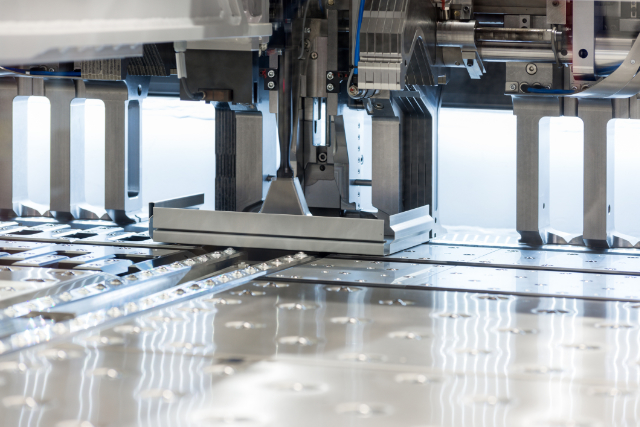

Metal Stamping and Hydroforming

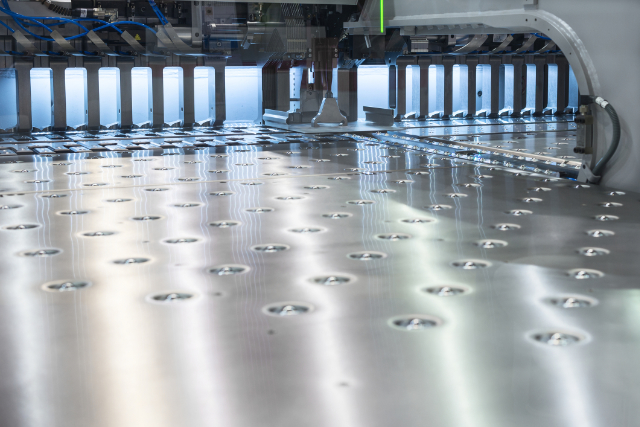

One of the misconceptions about the stamping process is that it is not as precise as it needs to be. However, the process is a very precise process that can also produce even the most complex and high tolerance parts. It is important that you choose the right stamping system to ensure that all of your parts will be produced properly.

Another myth about stamping is that the process cannot be used to create parts that are too complex. The stamping process uses various steps to complete the process; these steps will make it easier for the complex parts to be produced. This process also increases the overall process without it resulting in any type of inefficiencies.

Metal stamping is a process that is very cost-effective because it will produce a small amount of waste. Also, the process uses equipment that is automated, and this means the entire process can be operated on a regular basis without the need to have constant attention. Are you ready to produce a high number of simple and complex parts in an efficient and effective manner?

Contact us today for more information on stamping or the hydroforming process.

Leave a Reply