Improve Your Process With Friction Stir Welding

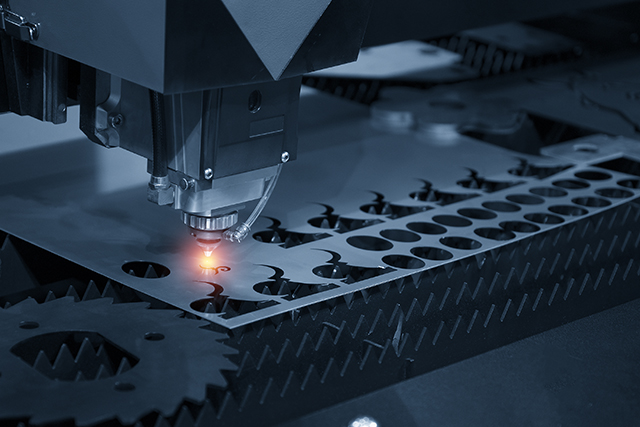

For many years, American Hydroformers has been one of the leaders in hydroforming technology and friction stir welding technology. Friction stir welding is a type of technique that offers a variety of benefits and advantages over one of the more traditional methods known as fusion welding. Friction stir welding has the ability to create a bond of any size, and this is one of the reasons why it has the ability to serve a wide range of industries.

Every industry continues to have changing priorities and a variety of advanced technologies that can be used to create a variety of applications. As a result, American Hydroformers continues to adapt the friction stir welding process to meet all the needs and demands of the industries. What are we doing to help the automotive, engineering, and aerospace industries move ahead?

Friction Stir Welding Provides Affordable Solutions

A variety of components can be created through friction stir welding. When friction stir welding is used, there will not be a need to bring in additional technology and machining. When there is no need for additional machining, you will be able to save a significant amount of money and time. Friction welding also has the ability to join more than one type of material, and this can also decrease costs. When you are able to join multiple materials, you will not have to worry about using the expensive materials until you really need them.

Greater Capacity

The machines that are used in friction stir welding are built with a large capacity and they are some of the most advanced machines in the industry. These machines and tools are created to meet all the demands that your industry requires. These machines are also designed to meet the quality requirements and part requirements for the industry.

Stronger Components

Many industries require the use of complex shapes, both large and small in size. These small and large parts are required to meet the reliability and quality standards so they can withstand any type of force or impact. When friction stir welding is used, the materials will be bonded together in order to create a stronger result. When the created components are stronger and made of high-quality, the components will have a longer life than they would if the fusion welding process was used.

Do you want to find out how friction stir welding can be used to improve your production and manufacturing processes? Contact us today for more information.

Leave a Reply