New Discovery, Implications for High-Temperature Metal Gas Forming

From time to time, new discoveries change the way we approach various aspects of industry and technology. Recently, the discovery of a new metal has us doing exactly that.

Getting The Perfect Finish With Hydroforming

When you are thinking about the multiple options that are available for working with any type of metal, many companies in the industry have chosen to use a process known as hydroforming. The manufactu …

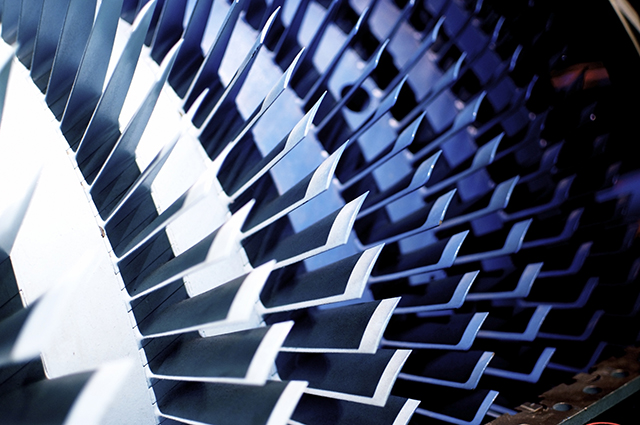

What Is Hydroforming: Benefits of Hydroforming

The hydroforming process has been used for quite some time in the manufacturing industry. The hydroforming process involves the use of stainless steel, aluminum, and other ductile metals. These ductil …

What Should You Know About Deep Draw Hydroforming?

Deep draw hydroforming is constantly in competition with other types of hydroforming processes that are able to create the same products or similar products. However, deep draw hydroforming has multip …

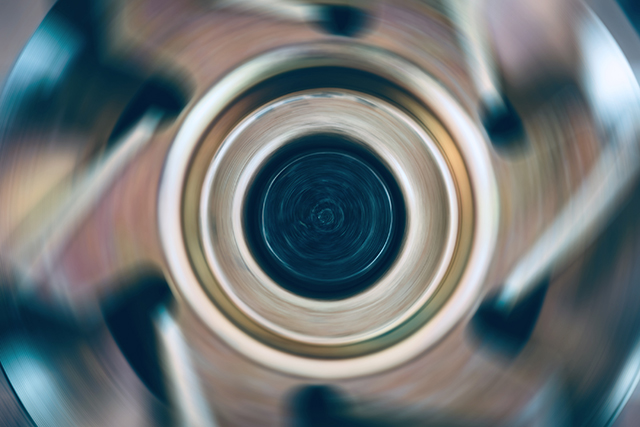

Tube Hydroforming: A Short History

Tube hydroforming: a short history. In many ways, the past holds the keys to the present. If those who have gone before us had not accomplished great things, we would not be where we are today. That’s …

The Curious Case of the Tesla Model 3

Tesla cars have been around for a while now, and successive models have been called everything from an “all-electric dream car” to an “eco-friendly gift to the motoring masses.” Of course, press for T …

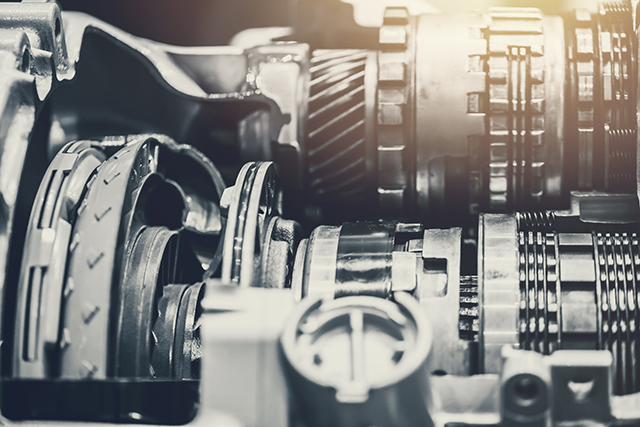

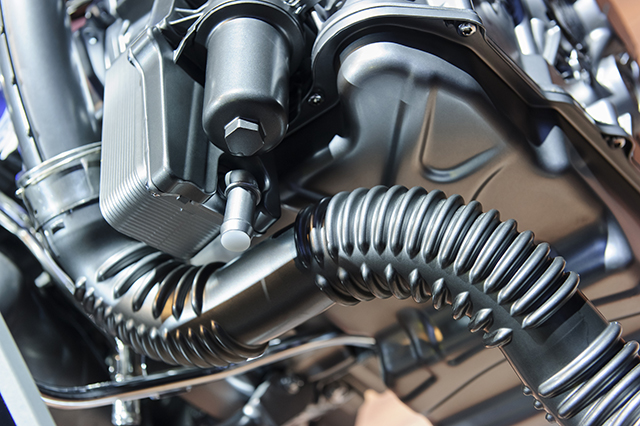

Hydroformed Components In The Automotive Industry

Do you own or operate a business that concentrates on creating customized and personalized motor vehicles? If you are, you will probably want to think about learning as much as you can about hydroform …

American Hydroformers News Roundup: Spring, 2018

Here at American Hydroformers, we like to keep abreast of the latest developments in the world of hydroforming. Every once in a while, we bring together a few interesting news articles for your instru …

Leveraging FEA for Pre-Production Needs

In some situations, speed is of the essence. Think of self-styled “fast food” or “quick service” dining establishments. If such restaurants are unable to provide quality food quickly enough, their cli …

American Hydroformers: Hydroforming in the Automotive Industry

Hydroforming is a fabrication method that is regularly used in the transportation and automotive industries. Hydroforming is used so often because it allows even the most complex shapes to be created …