Why You Can Trust Us with Your High-Temperature Metal Gas Forming

Here at American Hydroformers, we pride ourselves in keeping current with industry trends. That is just one of the many reasons why people to trust us with their high-temperature metal gas forming nee …

American Hydroformers: Not Just for the Midwest Anymore

We have written in the past about how American Hydroformers has taken center stage as the Midwest’s best and most convenient choice for those in need of hydroforming services. In addition to our wealt …

Are You Using The Right Hydroforming Tools?

Are you looking for a cost-effective method that will allow you to shape flexible metals that include the following?

brass

aluminum

alloy

Eyes on Fujitsu Laboratories for High-temperature Developments

As supply and demand continually fluctuate in any given industry, the global markets are constantly adjusting to keep pace. In order to meet demands in a timely manner, laboratory scientists and techn …

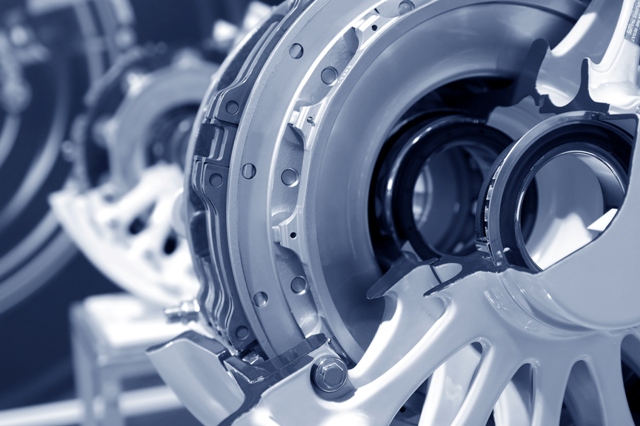

American Hydroformers: What Is Tube Hydroforming?

For many years, American Hydroformers has worked extremely hard to become a mainstay at the front of manufacturing. American Hydroformers makes it a purpose to invest a significant amount in materials …

American Hydroformers, Inc. to Present Tube Hydroforming Capabilities at FABTECH 2017 November 6-9.

Fort Wayne, IN-American Hydroformers, Inc. (https://americanhydroformers.com) announces that company representatives Mark Blasi, Bill Federspiel, Todd Champany, Max Barker, Tom Desnoyers, and Brian Cr …

American Hydroformers: Weighing in on Current CAFE Standards

Over the course of the last year, potential changes to federal regulations for automotive production in the United States have sent ripples through the auto industry. After months of speculation and m …

Hydroforming in the Midwest? Give Us a Call: American Hydroformers

Like all regions, the American Midwest has developed a certain reputation. While other sections of the country might be known for its stunning scenery (the West), beautiful autumn leaves (the Northeas …

American Hydroformers Metal Stamping: Creating High-Quality Pieces

Not everyone is going to realize this, but one of the most important pieces of the manufacturing process is metal stamping. Metal stamping provides a variety of benefits and advantages for companies i …

The Pros and Cons of the 2014 Cafe Standard Updates

Since 1975, CAFE standards have been in effect for the automotive industry. Since that time, these standards have been updated several times, culminating in changes announced in 2014, which are now in …