Hydroforming and Its Automotive Application

No matter how Fast and Furious one may wish they could be while driving, the notion of a safe car and high probability of accident survival is in the back of many individuals’ minds. Even when buying …

Hydroforming Aluminum helps Automakers meet 2025 CAFE Standards

Whenever there’s an opportunity to reduce the weight of a car or light-duty truck, it’s that reduced weight which moves us closer… “to [meeting] the 2025 CAFE (Corporate Average Fuel Economy) standard …

Why Is Tube Hydroforming A Preferred Solution?

The technique that is used to create hydroformed metal bellows

that are used in multiple industries is known as tube hydroforming. Tube

hydroforming is used in a variety of industries that produce par …

What Is Hydroforming: The Basics

Hydroforming is a unique process used to form metal. As a unique process, it also solves unique problems. Hydroforming makes a number of products possible that wouldn’t be possible through mainstream …

How a New Tube Hydroformed Instrument Impacts the World of Optics and Photonics

Automotive and aerospace engineers (among others) have used tube hydroforming as a means to supplement inferior design techniques, by decreasing weight and increasing tensile and ductile str ...

The Benefits Of Hydroforming

The process of hydroforming has been kicked around the manufacturing industry for quite some time. The process involves forming ductile metals such as stainless steel, aluminum, brass, and low allow s ...

How the CAFE Standards Influence Engineering & Design

We were all taught about idealized cantilever beams in college. Little did we know then, that even the simplest of parts have their own histories, and are affected by things as se ...

The Deep Draw Hydroforming Process & Advantages

In the 1940s, deep draw hydroforming became the forefront method for developing and manufacturing irregular shaped metal parts. Die style stamping became archaic, as it became inefficient in compariso ...

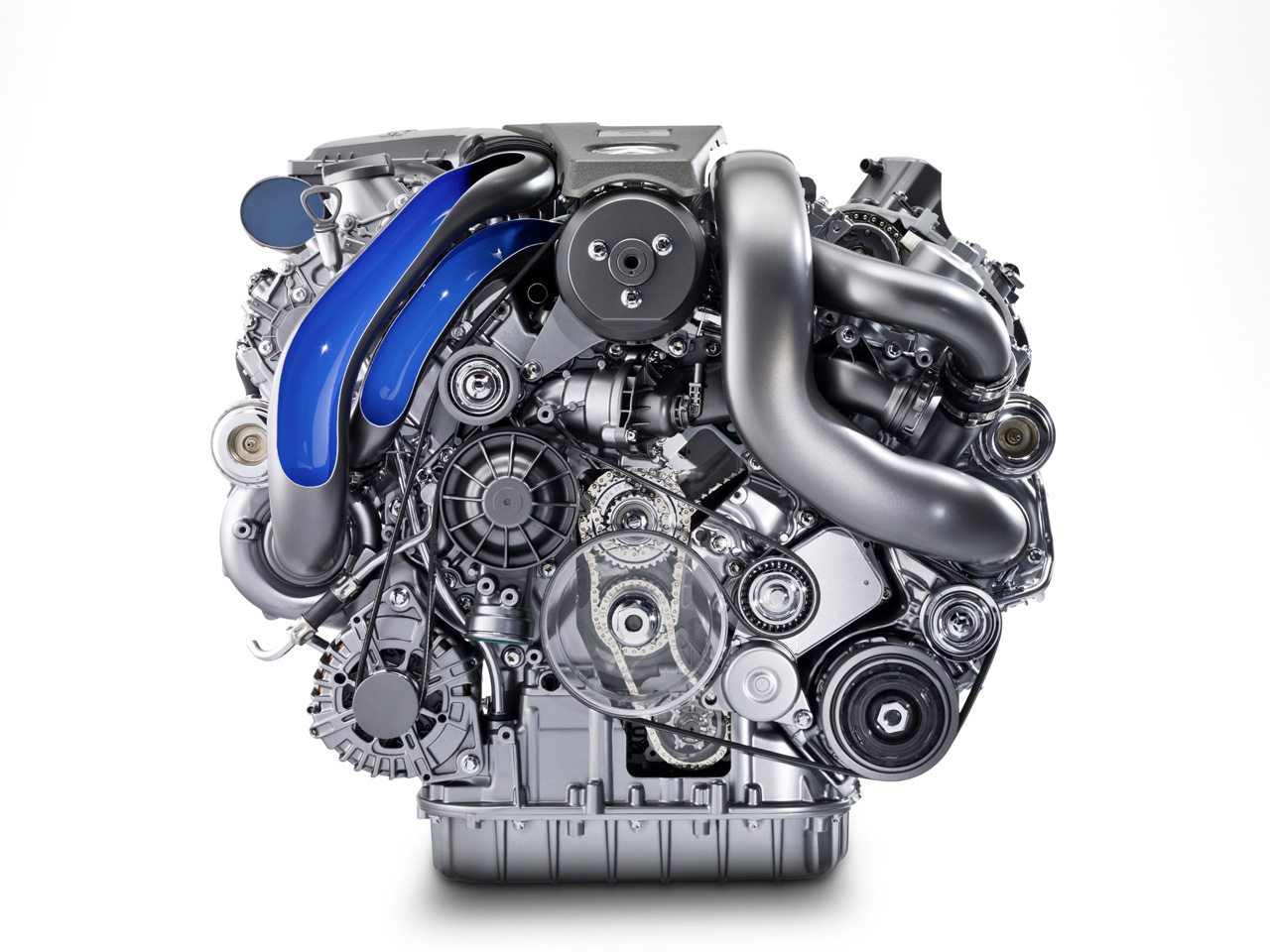

Mercedes-AMG selects hydroformed parts

As more and more automotive engineers begin to learn and source more hydroformed parts and components, the hydroforming industry sits on the verge of rapid growth. Mercedes-AMG selects hydroformed pa ...