Tube Hydroforming Will Continue To Have A Place In The Industry

While it may still be seen as one of the newer methods in the industry, especially when compared to the conventional or traditional stamping processes, tube hydroforming continues to have a large impact in the automotive industry and a host of other industries. Why is tube hydroforming having such a great impact in these industries? Why is tube hydroforming a popular choice over the older techniques?

During the production process, multiple steps will need to be taken in order to create a durable and solid finish. After the production process is over, a part that is formed through the hydroforming process will be able to carry more weight than if it is created with a conventional process. A tube-shaped created part will be able to carry a greater amount of weight when you compare it to metal stamped parts. When less welding is involved, you will have a product that is stronger and sturdier.

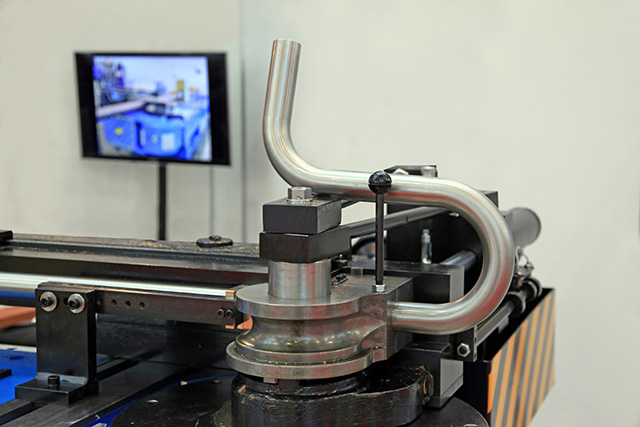

Tube Hydroforming

This is one of the reasons why tube hydroforming has become so popular in the automotive industry. Since the finished product will not be as heavy as metal stamped parts, the automotive industry will be able to create parts that do not have too much weight or density. Hydroformed parts will also cost less when compared to metal stamped parts. It is very cost-effective because there will not be a high amount of scrap waste, nor will it require a high amount of manpower to manufacture the products.

At one point, hydroforming was a process that was not widely known because it was used in only a handful of manufacturers, but now it is being used worldwide. When compared to the older techniques, the limits of hydroforming have been pushed far beyond those. Tube hydroforming will continue to be used now and in the future. We will continue to think of new ways to use tube hydroforming to create products that will meet and exceed expectations.

For more information on tube hydroforming, please do not hesitate to contact us today.

Leave a Reply