Aerospace Sheet Hydroforming Cuts Manufacturing Time

A prominent leader in hydraulic press and automation sheet hydroforming systems named Beckwood Press Company, has produced a hydroforming press especially catered to aerospace industry parts ...

Aluminum Hydroforming Leaves Its Mark

As automotive and mountain-biking companies begin to roll out sneak peeks at their 2015 lineups, it is becoming increasingly apparent just how much new advancements in hydroforming aluminum have affec ...

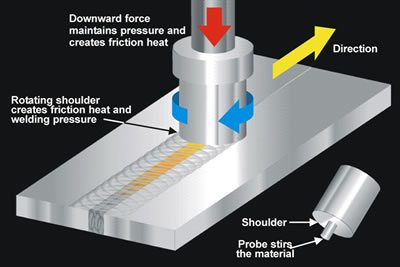

Friction Stir Welding: How Can It Be Useful To You?

Friction stir welding is used to create joints that are of the highest quality and of the highest strength. Friction stir welding was patented in 1991. The first applications that friction stir weldin ...

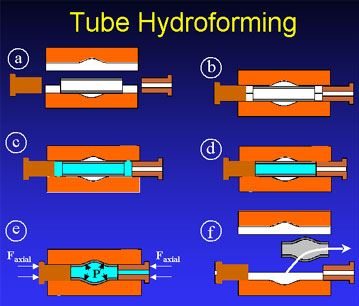

What is tube hydroforming?

Hydroforming is the process of using high pressured water to create custom metal structures to fit the needs of our clients. Centered in the Midwest since 2003, we have catered to a number of clients' ...

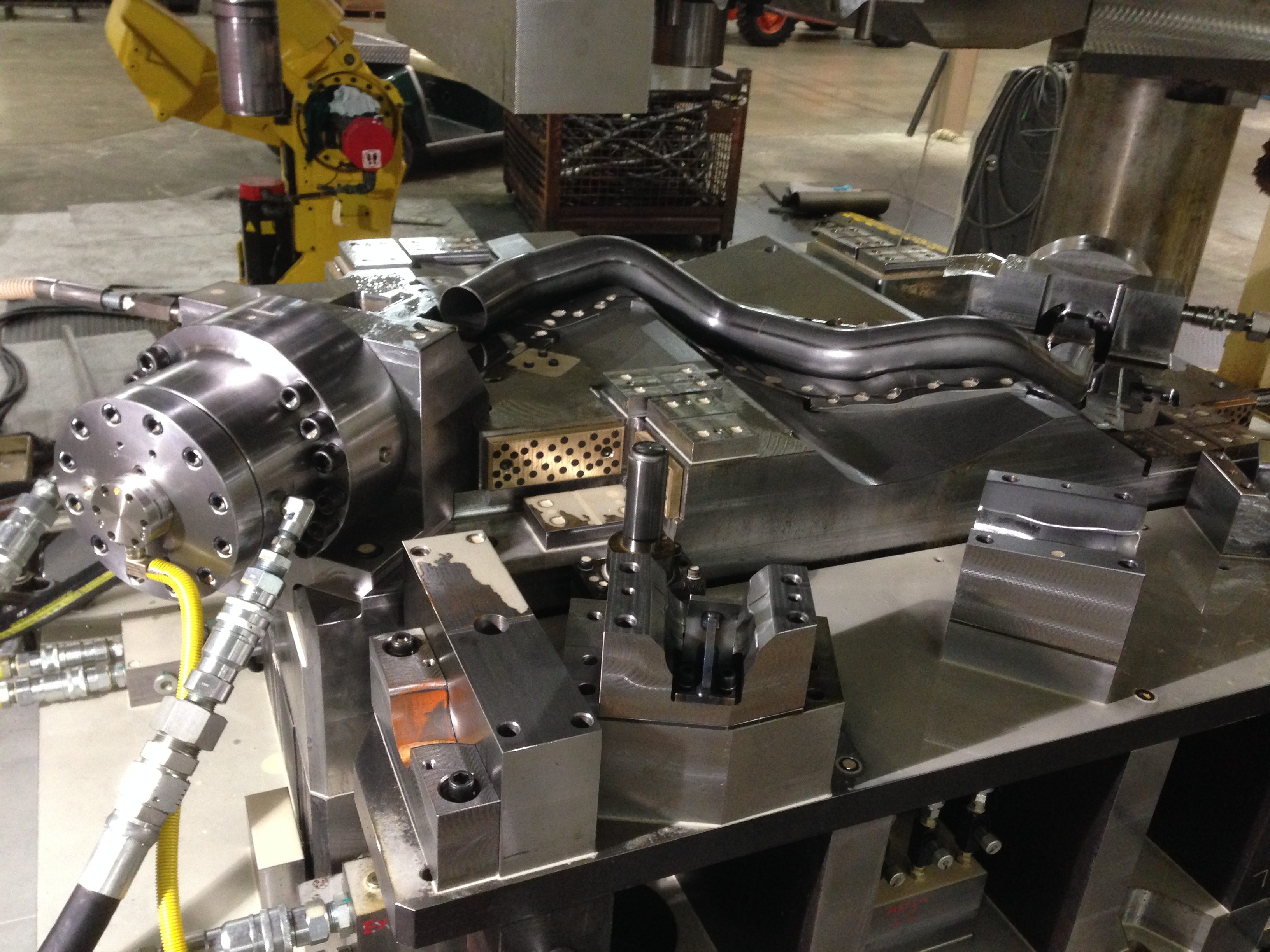

Three Applications for Tube Hydroforming Aluminum

While most people are only vaguely aware of the concept of hydroforming and its many benefits, even fewer are well-versed in the specifics of tube hydroforming aluminum. The unfortunate truth is that ...

Difference Between Research and Development Dies and Production Dies

As has been noted previously on this blog, there is a standard protocol followed for most hydroforming procedures: First a raw tube is loaded into hydroforming dies. Next, the hydroforming press ...

The art and the ingenuity of hydroforming

Hydroforming is not only a cost effective metal fabrication and forming process when compared to traditional stamped and welded parts, but it can also be a bit of art and ingenuity. Virtually all meta ...