Tubular Hydroforming And Other Innovative Techniques

Whenever you are working on a project, no matter how big or how small, you should always look for the best possible way to make the project successful. When you want the project done correctly, it doe ...

American Hydroformers, Inc. to be Featured on the Science Channel/Discovery Channel’s “How It’s Made” Television Program.

SUMMARY: American Hydroformers is proud to announce that the company will be featured on a segment of the Science Channel/Discovery Channel’s popular “How It’s Made” television program. This detailed ...

Research Predicts Rising Future for Metal Hydroforming, Stamping, Forging, and Rolling

The future of United States metallurgical manufacturing has never been more sound, according to a recent report on the ever-growing, ever-expanding billion dollar industry. Tube hydroforming, metal s ...

Next Generation Metal Stamping to Grow Significantly Worldwide Over Next Decade

We here at American Hydroformers are big proponents for the metal stamping industry. What began long ago as a means to bolster the manufacturing process into a single stage operation, has co ...

Report Says: Metal Stamping to Increase Thanks to Auto Industry

Metal stamping is a very important process to the manufacturing of automobiles. It plays host and is integral to a broad range of parts and finished goods. It transforms flat sheets of metal into ...

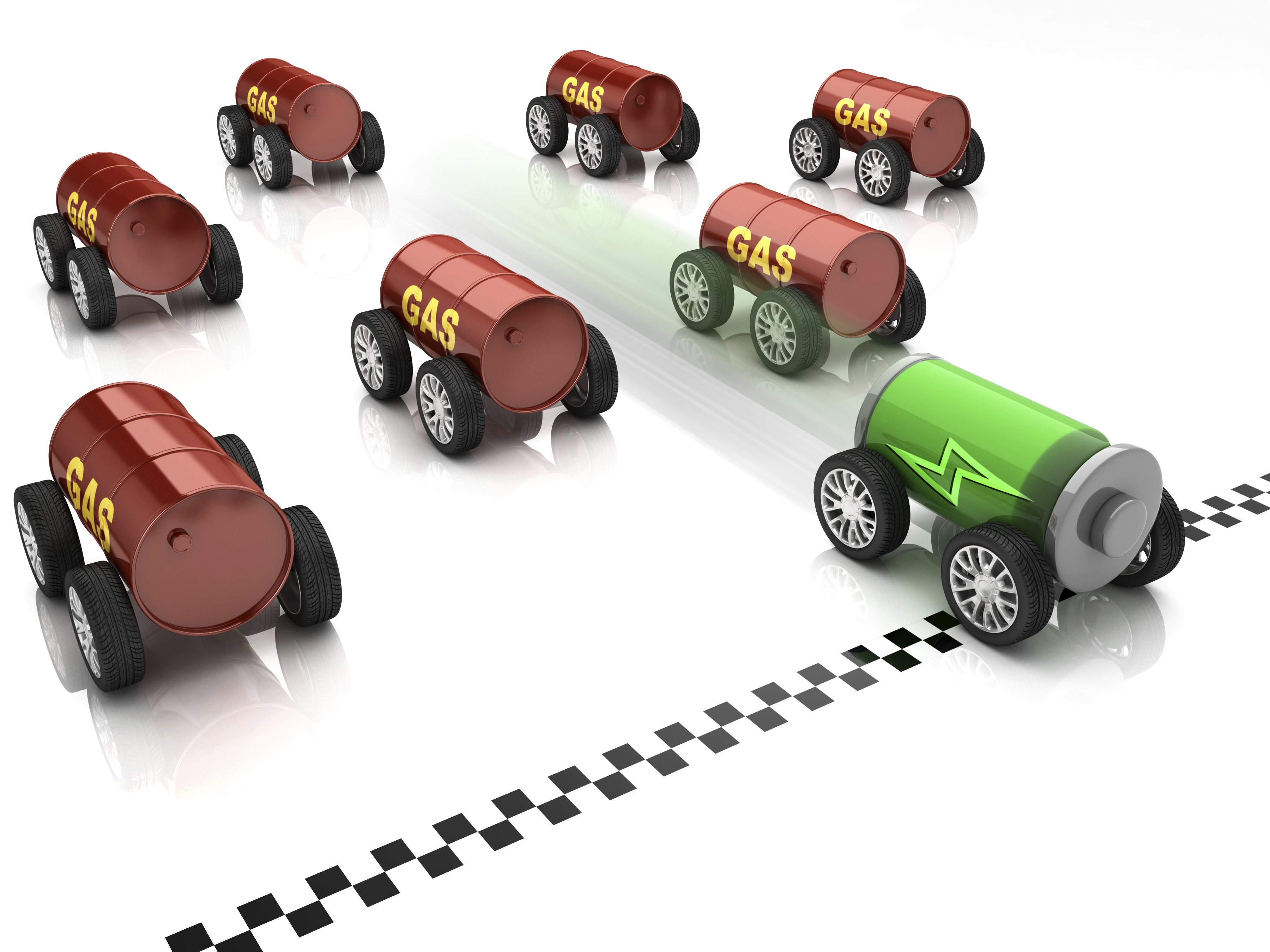

CAFE Standards to Increase Fuel Savings

CAFE standard is not a recipe for an espresso macchiato - even if that is your favorite drink. It is, however, the industry standard for keeping your espresso macchiato affordable by producing lighter ...