FEA or Finite Element Analysis Implementation: Are You Ready To Make The Step?

It does not matter where you look, you will always find information on how various companies and organizations have used an engineering simulation as part of their strategy when it comes to developmen …

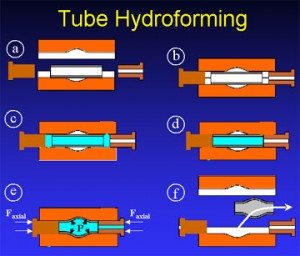

Tube Hydroforming vs. Sheet Hydroforming: What is Hydroforming?

What is hydroforming? Hydroforming is when the force of water, hydraulic fluids, or oils is used to shape a single part. There are two types of hydroforming and each has uses when creating products fr …

Deep Draw Hydroforming Benefits Your Daily Life

As deep draw hydroforming continues to become a reliable and viable source of production, people who rely on hydroformed parts can only benefit from its persistent innovation.

Information about new a …

Hydroformed Parts Key to Meeting CAFE Standards

Corporate Average Fuel Economy (CAFE) standards regulate the fuel economy of vehicles sold in the United States. Rather than requiring minimum fuel efficiency standards for each vehicle, CAFE requires …

Do You Have A Process Control System For Your Metal Stamping Production?

When you can control your manufacturing process, you will have a better chance of increasing your production, improving your quality, and reducing the overall costs. You need to have the right indicat …

American Hydroformers Employs Faro Edge Scan Arm HD

At American Hydroformers we recently obtained and implemented a new Faro Edge Scan Arm HD that enables enhanced product development, inspection, and quality control. As a 3D scanning and probing devic ...

How Tube Hydroforming Can Help Cafe Standards?

CAFE Standards: The Corporate Average Fuel Economy standards (CAFE) standard enacted in 2014 imposes fuel efficiency and green house gas emission standards on the manufacturers of cars and medium a ...

What is Hydroforming?

What is hydroforming? Hydroforming is an innovative method of pressing metal into the desired shape. It produces results similar to cold forming, but instead of simply pressing the metal with a mold ...

Though Struggles Exist, Hydroforming and Metal Stamping Thrive

U.S. manufacturing in the new tech age has brought with it many advances for those involved in the industries of metal stamping and hydroforming. However, at the same time, it has cont ...

Tube Hydroforming Process Leads to Amazing Bicycles

Though tube hydroforming has humble roots, it has taken those roots and firmly planted them in industry, design, and innovation. For instance, take a look at how much innovation has gone into bikin ...