Tubular Hydroforming And Other Innovative Techniques

Whenever you are working on a project, no matter how big or how small, you should always look for the best possible way to make the project successful. When you want the project done correctly, it doe ...

Hydroforming Aluminum Vs Stamped Steel

The rise of hydroforming as a viable manufacturing process which reduces the weight of resulting items is driving two distinct transitions in the industry. One of these is the switching from stamping ...

2016 CAFE Standards: What the Near Future Holds

Beginning in 2011, automobile makers had to meet a set of government regulations that had sat in limbo for many years. For many, this was the biggest change in fuel-economy standards since the 1970s C ...

Source Says: FEA Soon Available in the Cloud

According to a tech engineering firm known as Frame, CAD Windows apps, like FEA (Finite Element Analysis), can now be moved to the cloud, which will bring a hug change in how CAD operates. From an ...

3 of the Latest Hydroformed Components Hitting the Market

As we so often do, we like to focus on hydroformed components that are making waves in the modern world. From mountain bikes to car parts to aerospace design, hydroformed components and prod ...

American Hydroformers, Inc. to be Featured on the Science Channel/Discovery Channel’s “How It’s Made” Television Program.

SUMMARY: American Hydroformers is proud to announce that the company will be featured on a segment of the Science Channel/Discovery Channel’s popular “How It’s Made” television program. This detailed ...

5 Benefits of Hydroformed Components

In the middle of the US, located in what is universally known as the "breadbasket" of America, sits the heart of hydroforming in the Midwest. The sometimes seldom-known but vastly innovative productio ...

Research Predicts Rising Future for Metal Hydroforming, Stamping, Forging, and Rolling

The future of United States metallurgical manufacturing has never been more sound, according to a recent report on the ever-growing, ever-expanding billion dollar industry. Tube hydroforming, metal s ...

The Benefits Of Hydroforming

The process of hydroforming has been kicked around the manufacturing industry for quite some time. The process involves forming ductile metals such as stainless steel, aluminum, brass, and low allow s ...

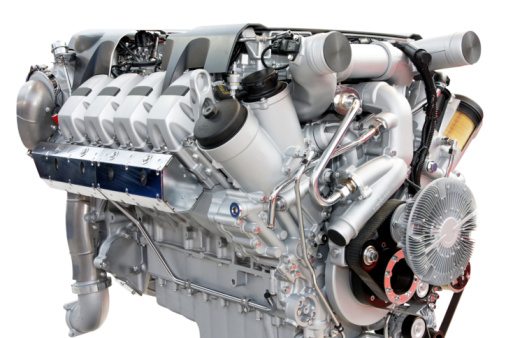

Hydroformed Components Make Trucks Stronger, Faster, and Better

We've talked in length before about how hydroformed components used in the automobile industry have helped to change the entire process. Every few months or so, we like to update our reader ...