3 Myths About Deep Draw Metal Stamping

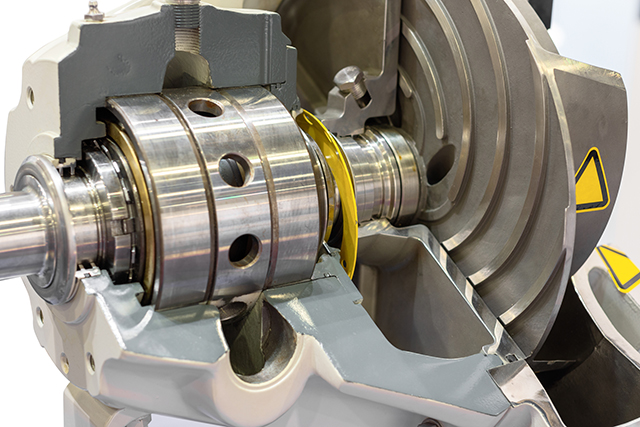

Over the course of many years, there have been numerous misconceptions about deep draw metal stamping and how the deep draw process works. For those who are unfamiliar with the deep draw metal stamping process, this is a manufacturing process that remains in competition with others in order to create a product that has a few similarities or one that is completely the same. However, the deep draw metal stamping process has a few major differences that separate it from the other methods and processes.

If you are new to the manufacturing industry, you may be one of the many people who believe the myths and misconceptions that are being shared about deep draw hydroforming. Here are a few of the myths we want to debunk today:

Myth 1: Deep Draw Metal Stamping is Not For Complex Parts

This is not true. Deep draw metal stamping is not just a process for the simple parts. This process can absolutely be used to create even the most complex of parts. There are stamping presses that have the capability to form durable and flawless parts.

Myth 2: The Deep Draw Metal Stamping Process is too Expensive

This is also false. The deep draw process is an unceasing process, and this makes it one of the most affordable processes that are available to you. This process is also one of the fastest processes that you can use. When you use the deep draw process, you will quickly discover that the costs will decrease as the number of parts you need to produce increases.

Myth 3: Deep Draw Metal Stamping Cannot Make Strong Materials

This is not true. This is one of the most common myths and misconceptions about the deep draw process. Many people believe that the deep draw process will cause the material to stretch, which will eventually damage it. The force that is placed on the material will not weaken it, but it will strengthen it. There may be some stretching of the material, but the stretching will not be very significant.

Have you fallen victim to any of these myths and misconceptions about deep drawing? If you would like to learn more about this process, please do not hesitate to contact us today.

Leave a Reply