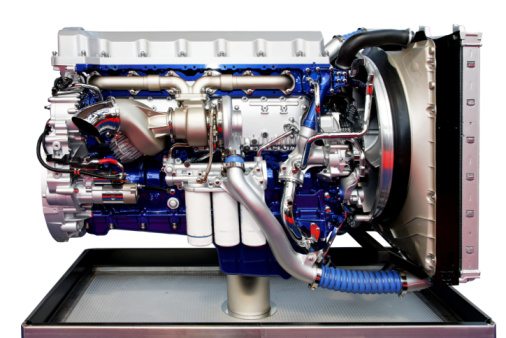

Hydroformed Components Make Trucks Stronger, Faster, and Better

We've talked in length before about how hydroformed components used in the automobile industry have helped to change the entire process. Every few months or so, we like to update our reader ...

Deep Draw Hydroforming Aids in Medical Device Manufacturing

It has long been established that deep draw hydroforming is a technology that has staying power. The process in which deep draw hydorforming follows makes it a powerful solution for a variet ...

Aluminum Hydroforming Outperforming Steel Stamping

Hydroforming aluminum products has been around for the last few decades in some for or another. In the beginning, it was perfected to manufacture lightweight parts for the automotive industry as cars ...

Hydroformed Components Still Huge Part of Manufacturing

We have long highlighted how hydroformed components are integral to manufacturers. From the kitchen sink to sports cars, hydroformed parts continue to lead the charge of innovation, and chan ...

How the CAFE Standards Influence Engineering & Design

We were all taught about idealized cantilever beams in college. Little did we know then, that even the simplest of parts have their own histories, and are affected by things as se ...

The Budding New Technique of Friction Stir Welding

A relatively young technique in the field of welding, friction stir welding was invented then scientifically proven as a viable method in December of 1991. By definition it is a 'solid-state joining p ...

Aluminum Hydroforming Leaves Its Mark

As automotive and mountain-biking companies begin to roll out sneak peeks at their 2015 lineups, it is becoming increasingly apparent just how much new advancements in hydroforming aluminum have affec ...

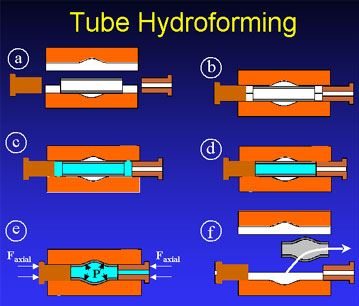

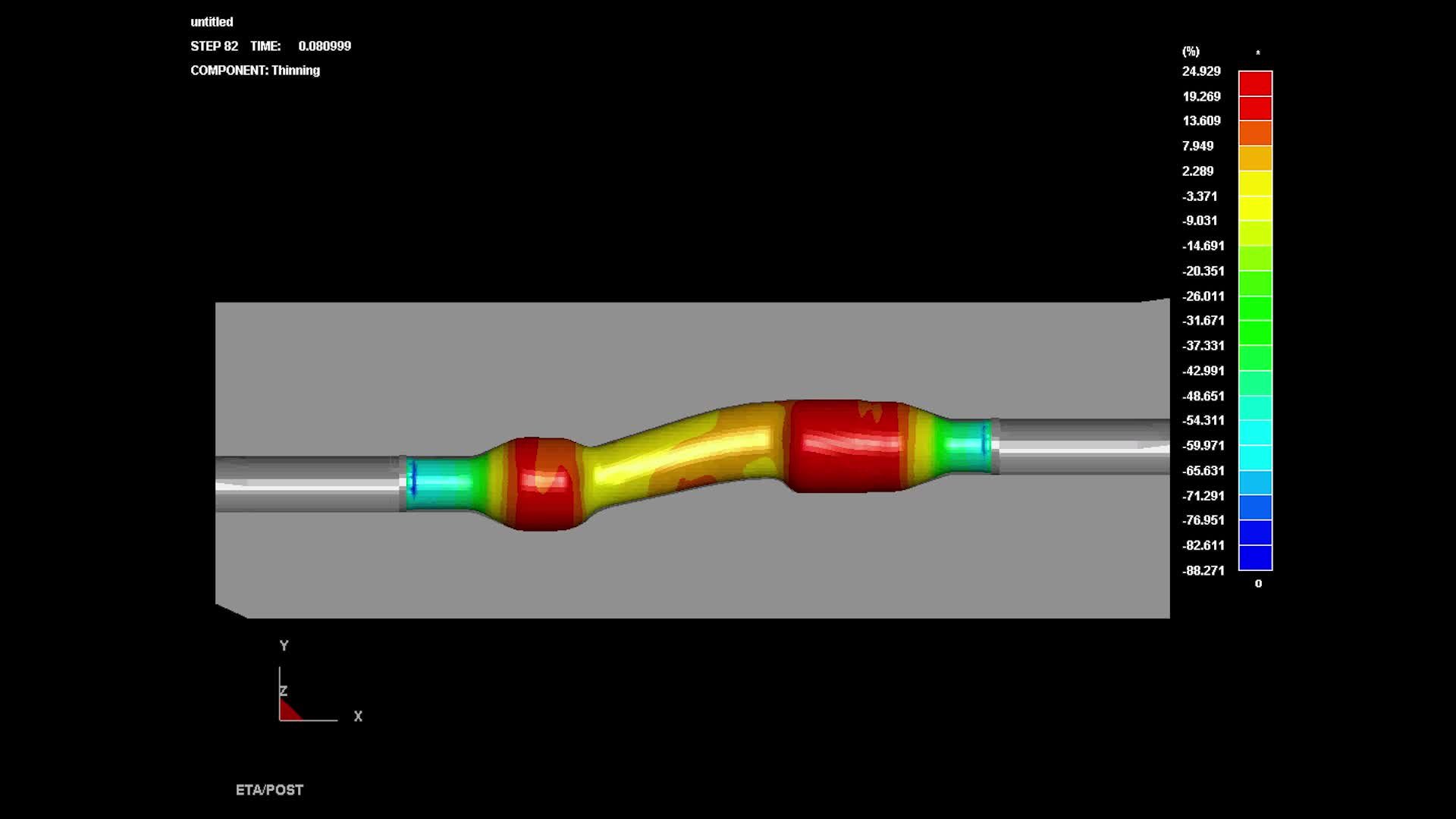

What is tube hydroforming?

Hydroforming is the process of using high pressured water to create custom metal structures to fit the needs of our clients. Centered in the Midwest since 2003, we have catered to a number of clients' ...

Hydroforming Aluminum Can Help Reduce Weight Of Components

Hydroforming is a method that shapes metal into strong pieces that are also light, in regards to the weight. There are many different industries that use hydroforming. However, the vehicle industry is ...

What is Hydroforming

Every time you drive a motor vehicle, fly in an airplane or ride a bicycle, hydroforming was likely used as part of their manufacture. Hydroforming provides a number of advantages when compared to oth ...